Top maintenance tips

As a fleet owner or manager, you are constantly balancing many aspects of running a fleet operation efficiently, and maintenance issues are the last problem you need. Knowledge is power, so let’s look at the top maintenance-related challenges you might encounter so that you can be proactive in preventing downtime.

Help for light-duty trucks

One of the most overlooked items on a refrigerated light-duty truck is the refrigeration unit. If you align the trucks planned maintenance (PM) schedule to coincide with the chassis PM, it can help maintain both systems. Pay particular attention to the fluids, belts, and electrical system. Overlooking these can be a costly mistake.

No base

Do you have some vehicles that do not return to the same base? Here are some tips to keep in mind:

- Follow a maintenance schedule

- Adhere to a pre-trip inspection

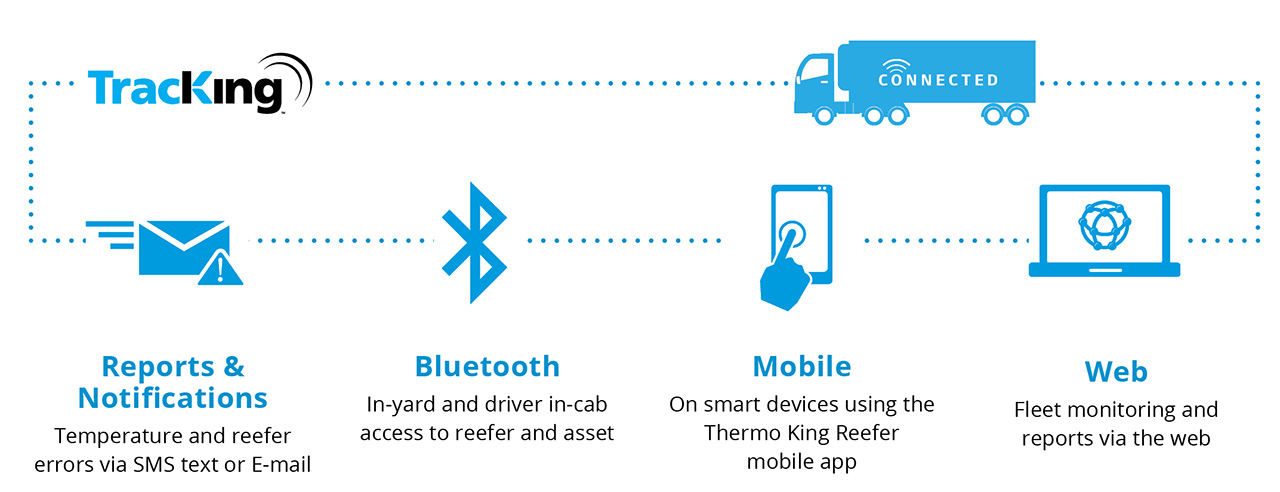

- Use telematics to remotely monitor your units

- Be proactive with maintenance