Q: Prior to 2013, an ultra-low emissions transport refrigeration unit (ULETRU) was not seen in the Trailer market. Why did Thermo King choose to introduce a ULETRU Trailer product at that time?

A: In short, the timing was right. We knew that if we could create a unit that would meet ULETRU emission standards and improve the overall total cost of ownership (TCO), we would have the best possible solution for our customers. Our goal was to be intentional and forward thinking to develop a platform of new Trailer TRUs that reinforced Thermo King’s position as the transport refrigeration industry leader.

And that’s what we did. We started the development work with the goal of designing a Trailer TRU that would meet the most stringent diesel engine emissions standards when EPA Final Tier 4 standards began applying to TRU products in 2013. And we made sure it would offer the best customer TCO available.

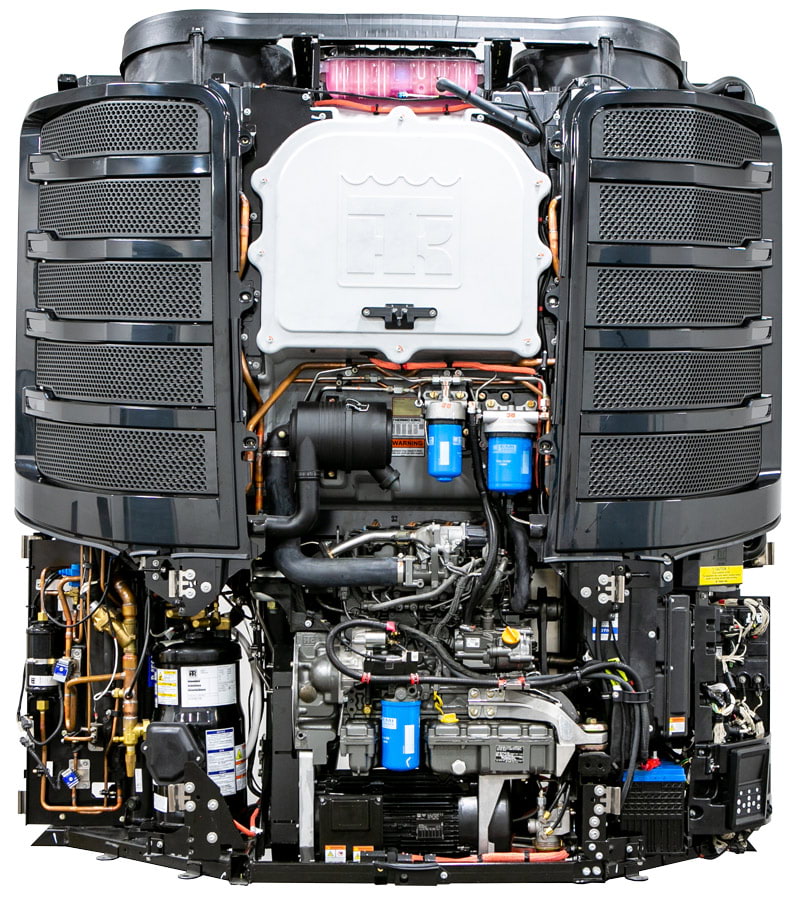

We partnered with a diesel engine supplier to develop an engine that meets >19kW power category ULETRU emission level without the need for a diesel particulate filter (DPF) to reduce customer maintenance costs. This was achieved by using a common rail fuel injection system, Exhaust Gas Recirculation (EGR), Diesel Oxidation Catalyst (DOC) after-treatment, and associated engine controls.

Design of the Precedent system was centered around optimized efficiency to lower customer operating costs. We knew the engine design required to meet EPA Final Tier 4 >19kW emissions standards would add cost to the TRU. By reducing maintenance and operating costs, plus improving resale value on the unit, the Precedent design provided overall TCO value to customers.