June 1, 2012

Delivering Fleet Sustainability through Innovation

Thermo King Proud to Partner with Deli Express® Supplier Team

Deli Express®/E.A. Sween Company is a family-owned foodservice company with a special interest in conserving natural resources through fleet sustainability. When the company set out to find a way to reduce fuel expenditures and improve its fleet carbon footprint, it turned to several key suppliers for help. Thermo King is proud to be one of the collaborative partners that helped the company achieve its goal.

A Thermo King customer for five years, the Eden Prairie, Minnesota-based Deli Express/E.A. Sween has proved to be a true partner.

“Gregg Hodgdon, head of Deli Express®/E.A. Sween Company’s fleet operations and a certified automotive fleet manager (CAFM), came to us when the company wanted to expand from a traditionally all-frozen transportation fleet with cold plate technology to one with multi-temperature capabilities,” said Dan Vesper, sales representative with Thermo King of St. Paul, the company’s local Thermo King dealer. “It’s been a great partnership from the beginning as Thermo King is just as committed to finding more efficient and sustainable business practices as Deli Express.”

That relationship was a key reason Hodgdon turned to Thermo King when, with the support of fleet management partner Automotive Resources International (ARI®), he began the process of developing an innovative new refrigerated truck design that could significantly improve fuel economy without sacrificing customer satisfaction.

Deli Express/E.A. Sween Company’s vision was a fuel-efficient, lightweight, and cost-effective refrigerated truck.

The dream team

To make this happen, Hodgdon identified collaboration partners who shared his innovative vision for sustainability and understood the value this project could ultimately drive to his company’s bottom line.

In addition to Thermo King, the final roster included Isuzu for the diesel chassis, Johnson Truck Bodies for the lightweight shell, and ARI for the truck expertise and analytical tools that would help calculate the design’s impact on cost and efficiency.

The four vendors worked in tandem with Deli Express®/E.A. Sween Company to ensure that all required components would work in concert together, and that the combination would ultimately yield the most significant fuel efficiency increase possible.

“Our carefully selected fleet partners bring a higher level of expertise and creativity to fleet sustainability,” said Hodgdon. “Without their support, our company’s sustainability transition would have been far more difficult. We look forward to future collaboration in reducing our environmental impact.”

The technology

Isuzu’s ECOMAX features a turbocharged, four-cylinder, 3.0L engine that delivers 150 horsepower and 282 ft.-lbs. torque. This offers plenty of power to move the lightweight body, daily cargo load, and driver effortlessly. Its electronic high-pressure common rail fuel injector system helps to maximize fuel economy. Other notable features include a premium low cab forward design offering superior visibility and maneuverability; a B10 engine life rating of 310,000 miles; an Aisin six-speed automatic transmission with double overdrive; a 12,000 pound Gross Vehicle Weight Rating (GVWR); a reduced curb weight due to the use of a thinner gauge steel frame; and a base warranty of 3 years/unlimited miles. Learn more at www.isuzu.com.

Johnson Truck Bodies’ GuardianLT is larger than previous truck body designs, yet offers unparalleled weight savings. The body is lightweight and durable allowing it to be used several times on different chassis – the true definition of sustainable. In addition, the GuardianLT offers a very high thermal rating which results in reduced consumption of the electricity and fossil fuels needed to keep the body and cargo area at the desired product temperature. Reducing energy consumption also meant lower fleet operational costs for Deli Express®/E.A. Sween Company. More information can be found at www.johnsontruckbodies.com.

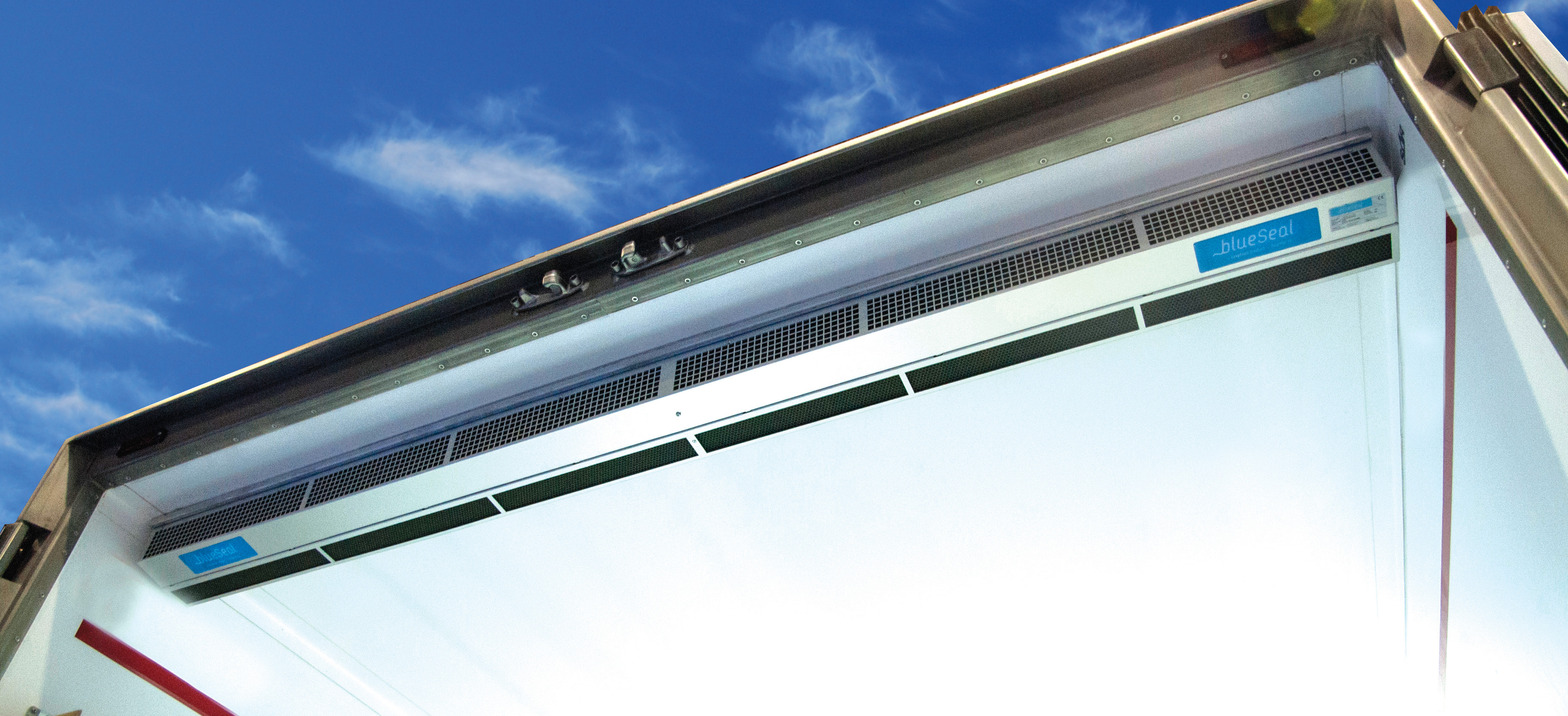

Thermo King’s new V-520 RT SPECTRUM direct drive refrigeration unit is ideally suited to handle Deli Express®/E.A. Sween Company’s requirements for both the fresh and frozen compartments on the truck. It is a multi-temperature, slim line rooftop unit.

An innovative heating system enables productivity gains by allowing specialized thawing applications to occur on the truck rather than in a warehouse. “Previously, Deli Express would have to move frozen sandwiches out of a warehouse to a thawing area each night, and then load the product onto trucks in the morning prior to distribution,” explained Vesper. “The V-520 RT eliminates that middle step, providing a leaner operation before deliveries even begin.”

The V-520 RT’s slim profile roof mount condenser provides the necessary refrigeration capacity while presenting an aerodynamic profile to maximize the overall truck efficiency. The refrigeration system is capable of maintaining the required temperatures throughout Deli Express®/E.A. Sween Company’s geographic reach which includes both hot and cold climates.

The SPECTRUM unit uses electric standby to reduce fuel consumption and corresponding emissions. Electric standby also enables rolling warehouse applications where the product is stored on the truck for later sale. The unit also uses a low amount of refrigerant, which reduces its impact on the environment. Visit www.thermoking.com for more information.

Proven performance

Deli Express®/E.A. Sween Company started with two pilot trucks approximately eight months ago. The company now has six ECOMAX trucks in service with 12 more expected to be placed in service as the project expands this year. The vehicles are demonstrating impressive results with nearly 50 percent improvement in fuel economy.

ARI recently analyzed the emissions associated with the ECOMAX trucks compared to other Isuzu NPRs in the fleet. The ECOMAX units are currently emitting approximately 700 pounds less of carbon dioxide on a monthly basis. Extrapolating a similar usage pattern over a 12-month period, the ECOMAX trucks will emit 4.2 tons less of carbon dioxide. These results are proof that it is possible to improve a fleet’s carbon footprint through weight reduction and efficient technologies while still utilizing a traditional fuel source.

“The success of the Deli Express / E.A. Sween Company project was due to amazing relationships between the customer, ARI, Isuzu, Johnson Truck Bodies, and Thermo King,” said Scott Bates, truck product manager for Thermo King Corporation. “It’s so rewarding to be part of a team that simply wants to help the customer operate more efficiently … and works tirelessly to make it all come together. That’s what innovation is all about.”

About Deli Express®/E.A. Sween Company

Deli Express®/E.A. Sween Company, founded in 1955, currently has over 850 employees and is a leading manufacturer and supplier of hot and cold sandwiches in the United States. Over 75 million Deli Express® sandwiches are sold every year in more than 26,000 convenience stores, grocery stores, drug stores, vending and other food outlets across the country. Deli Express® route trucks provide direct store delivery in 26 states of Deli Express® branded sandwiches, burritos, bakery and other foodservice programs. For more information about Deli Express®, visit www.deliexpress.com.

Customer: Deli Express®/E.A. Sween Company | www.deliexpress.com

Dealer: Thermo King of St. Paul | http://www.tkstp.com/