July 29, 2019

NFI Intermodal

Innovating the Temperature Controlled Supply Chain via the Railways

NFI Intermodal is a division of the diversified NFI Industries, a privately owned international transportation and logistics company that takes pride in delivering completely customized supply chain solutions that are fast, smart and responsible. Since 2005, NFI Intermodal has played an instrumental role in successfully meeting evolving customer needs for reliable capacity, consistent service and low costs when moving goods from factories or import distribution centers to regional distribution centers via rail. The company expanded in 2010, entering the refrigerated container business for the first time and making an immediate impact on the industry. In short, the company has provided the technology and service that has both modernized and strengthened the rail transport industry.

Why Temperature Controlled Intermodal?

With intermodal being the fastest growing mode of transportation, NFI Intermodal wanted to grow its offerings to better address rising customer needs for consistent capacity, good service and low costs in the quickly growing temperature controlled supply chain. And they wanted to do it the right way … with updated, dependable technology that was both environmentally responsible and efficient.

“We realized that the old way of operating the refrigerated intermodal business utilized antiquated and inefficient trailer on flatcar (TOFC) intermodal technology,” said Ike Brown, one of NFI’s owners. “In the 1990s and early 2000s, all of the major railroads made a major leap forward in dry van domestic intermodal technology through the proliferation of domestic 53-foot double stack containers on flatcars (COFC). COFC technology revolutionized the domestic intermodal business by enabling trains to handle almost twice as many shipments per train as the old TOFC technology. This substantially drove down costs for railroads, intermodal carriers and shippers.

“We wanted to bring the same technological and cost advantages that COFC technology brought to the dry supply chain to the temperature controlled supply chain.”

And that’s exactly what Brown and his NFI Intermodal team did.

Technological Partnership

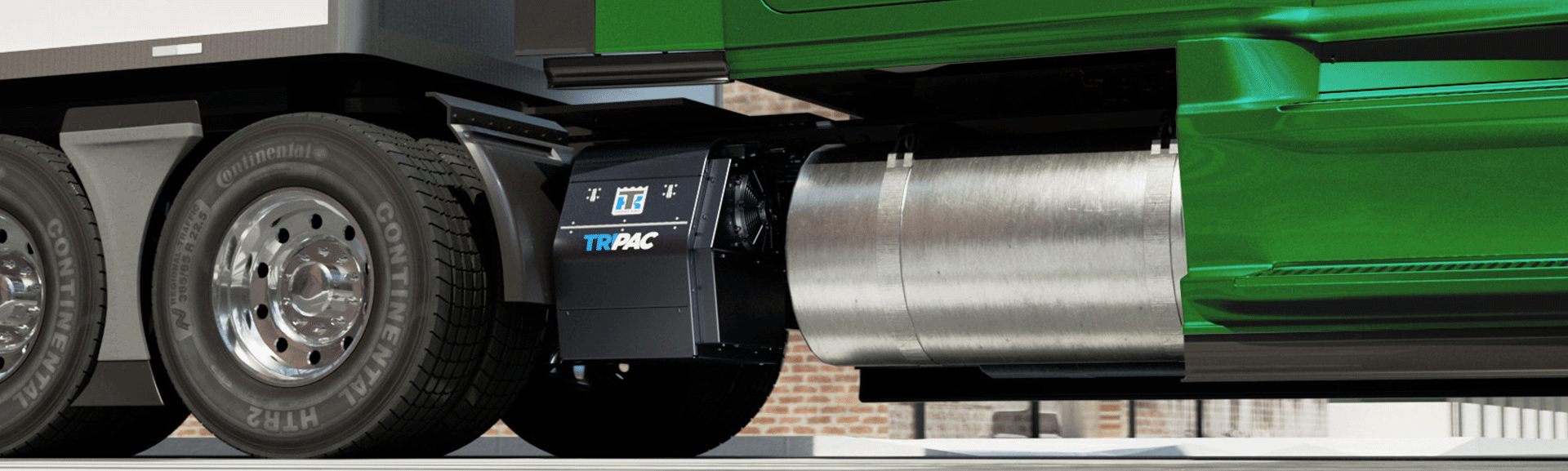

NFI Intermodal worked with its equipment partners Hyundai and Thermo King to overcome technical and economic hurdles and became the first carrier to launch domestic temperature controlled containers in the United States. And today, just two years since it entered the market, NFI Intermodal boasts a fleet of 120 state-of-the-art refrigerated containers, all with Thermo King SBRR units capable of cooling to -20 degrees F, a 120 gallon front mounted fuel tank, TracKing™ telematics for 24-hour monitoring, and Thermo King SVC guaranteed maintenance coverage to keep the units tuned and in top performance as they roll across North America.

Reliable Refrigeration is Key

“We chose Thermo King as our refrigerated partner from the beginning,” says Scott Webb, senior vice president NFI Intermodal. “We believed that the lessons learned from Thermo King’s extensive refrigerated boxcar experience would result in the best overall experience for us in the refrigerated container segment. And we have not been disappointed.

“Thermo King’s team, led by Doug Moore (rail business development/applications manager), Rick Boily (rail service manager), Frank Pryzwara (district sales manager), Freddy Munoz (district service manager) and Ed Brown (sales manager for Thermo King dealer CSTK), has brought tremendous rail knowledge, experience and service, enabling NFI Intermodal to create an industry-changing refrigerated container product.”

Thermo King’s Rail Ready units were specifically engineered to stand up to tough, unattended rail environments, and come in the COFC double-stack packaging NFI Intermodal was seeking.

“The SBRR units are reliable, offer industry-leading fuel economy and are backed by Thermo King’s extensive dealer network for all maintenance work. The SR-2 and SR-3 controllers are easy to use, and coupled with OptiSet™ Plus, are unbeatable when it comes to optimizing unit performance,” continues Webb.

Thermo King’s OptiSet Plus is a controller interface program that helps reduce shipper and operator error by providing commodity profile settings. Developed with food and agriculture experts, the settings are customizable to meet individual customer needs and parameters.

Remote Monitoring and Streamlined Processes

A dependable satellite tracking system was another key feature that NFI Intermodal wanted as part of its refrigerated container offering for customers. Thermo King’s TracKing system was the perfect fit.

“The telematics package is a critical component to our success and commitment to customer service excellence,” says Webb. “It’s a much more streamlined process when the telematics comes from the same vendor partner who manufactures the actual refrigeration unit. Updates can be made remotely, saving both time and labor expenses. It also allows one contact for any issue or question that comes up … whether it is associated with telematics, maintenance or invoicing; it can all be addressed through one Thermo King contact. This makes life much easier for us and our customers.”

With cross country routes from California to the upper Midwest and Northeast, as well as the Pacific Northwest and Texas and Florida, effective tracking during each trip is essential. Especially when the typical products hauled include frozen and chilled food, food ingredients, beverages, and temperature-sensitive ice cream.

NFI Intermodal takes both its remote monitoring with TracKing and its manual checks very seriously throughout each trip. Pre-trip monitoring and precooling are conducted, as well as manual fuel and temperature verifications at rail terminal in-gate checks. In addition to the automatic alarms programmed into TracKing, the system is manually monitored twice-daily while the product is being transported.

“It’s NFI Intermodal’s commitment to superior service that makes the company so successful,” says Doug Moore, Thermo King rail business development/applications manager. “They understand that intermodal success is based on relationships – with vendors, customers and carriers. They understand their customer needs and the environmental benefits of rail transport, and they’ve invested in the right technologies that truly deliver. They are a phenomenal partner and innovator in the world of intermodal transport.”

Together with its unique container design and its rail partners, Union Pacific and CSX, NFI Intermodal has drastically decreased the cost of domestic temperature controlled transportation while providing excellent service and consistent capacity. As a result, NFI has experienced rapid revenue and profit growth since launching refrigerated intermodal service. In fact, it has become the company’s fastest growing segment, continuing NFI’s legacy as a product innovation leader.

More information on NFI Intermodal can be found at www.nfiindustries.com/services/nfi-intermodal.

Learn more about Thermo King’s Rail Ready products at www.na.thermoking.com.

Customer: NFI Intermodal | www.nfiindustries.com