November 14, 2023

Decarbonizing Your Fleet with Innovative TRUs

By leveraging advancements in transport refrigeration unit (TRU) technologies, fleet managers can reduce transport- and storage-related emissions, while assuring adequate cargo cooling.

As the world grapples with the impacts of climate change and prospects of its further progression, organizations everywhere are coming together to alter the trajectory. These efforts have rapidly extended to the transportation sector, but decarbonization introduces unique challenges, especially in these settings because it often requires changing the way some everyday operations are executed.

Fleet managers are striving to simultaneously:

- assure reliable, high-quality cold chain shipping and storage while maintaining safety protocols

- comply with state and local regulations

- take advantage of governmental rebates, grants, and decarbonization incentives, and

- achieve corporate environmental, social, and governance (ESG) goals.

Transport refrigeration unit (TRU) manufacturers have a responsibility to help guide the industry in decarbonization approaches by developing a variety of sustainable technology options, such as electrification and alternative fuel sources, to meet current and future regulations. Though it comes with challenges, early adoption of new technology provides the opportunity for fleet operators to establish themselves as innovative environmental stewards. The right moves can help reduce an organization’s carbon footprint by choosing a sustainable future for transportation fleets.

Decarbonization opportunities

Decarbonization requires more than a simple change a company can implement instantaneously. It instead requires an organizational mindset, and applying it across an entire fleet creates challenges, particularly in the areas of regulatory requirements, infrastructure, and ESG.

Regulatory

This requirement is especially relevant in certain locales with net-zero emissions (ZE) mandates. For example, according to the California Air Resources Board (CARB) statute 2477.5(b)(1), “beginning December 31, 2023, no owner or owner/operator shall operate or cause to be operated in California, any (straight) truck TRU in the owner’s truck TRU fleet, unless the fleet meets or exceeds the required ZE truck TRU fleet percentages specified in [Table 1].”

|

Compliance Date as of December 31

|

Required ZE Truck TRU Fleet Percetange

|

|---|---|

|

2023

|

15%

|

|

2024

|

30%

|

|

2025

|

45%

|

|

2026

|

60%

|

|

2027

|

75%

|

|

2028

|

90%

|

|

2029 and thereafter

|

100%

|

Table 1: Required fleet percentage zero-emission truck TRU to comply with the California Air Resources Board statute 2477.5(b)(1) by year.*

The required number of ZE truck TRUs is based on the truck TRU fleet size reported to CARB on December 31 of each year. According to CARB, 2477.13(b), TRU OEMs shall not manufacture a truck TRU for sale or use in California beginning December 31, 2023 unless it is a ZE truck TRU. More regulation details can be found here.

CARB is one of the first regulators to begin mandating decarbonization among fleets, and some other locales are expected to follow suit.

Infrastructure

As with most significant changes, decarbonization does not take place overnight. Instead, the migration to new, greener equipment occurs one element at a time, so it is impractical for a large segment of critical services, like commercial transport, to suddenly and simultaneously shift to entirely new energy sources.

Similarly, truck and TRU OEMs cannot instantaneously change production because of dependencies on supply chain and technology changes that must be proven to succeed in a dynamic industry. The transition to electrical energy from fuels is also throttled by timelines required for utilities to plan, permit, and construct infrastructure for electrical distribution, along with manufacturing requirements for components like transformers and chargers.

The limitations of infrastructure impact the viability of electric long-haul trailer TRUs in particular. Even if commercial dealers could begin producing solely EVs tomorrow, the energy infrastructure required in key freight corridors is not currently at scale to handle the power levels and number of connections necessary to keep cargo on the move and properly climate controlled.

There are two critical variables for sufficient charging infrastructure. There must be enough total power to keep trucks running, and it must be available in the right locations to serve a fleet’s operational logistics. The constraint on power supply is typically most acute in areas with a heavy preponderance of distribution centers.

Adding substantial amounts of EV charging stations for commercial vehicles, like trucks and trailers with TRUs, could strain local electrical transmission and distribution (T&D) networks. Many power companies across North America are eager to help scope and size charging requirements, but they may be unfamiliar with associated variables for transport refrigeration power, such as peak charging power, number of units charging simultaneously, TRU pulldown duration, and others. But the provision of power to these charging stations will require massive upgrades to T&D systems, which will take time to implement.

ESG climate

Corporations are taking greener ESG stances than ever before with the rise of global climate concern and pressure to operate sustainably. For fleet operators, this means increasing efficiency, and scrupulously searching for opportunities to save energy and reduce product waste.

This challenge to the status quo presents an innovation opportunity, but change can be difficult. Nevertheless, sustainability initiatives must be part of corporate conversations because environmentally conscious practices are important to consumers and stakeholders, as well as to the general public.

The Thermo King decarbonization approach

In the face of these challenges, Thermo King is helping its customers decarbonize their operations by meeting them where they are in the sustainability journey, providing a wide range of temperature-controlled transport solutions to aid carbon emission reduction efforts.

Their technology empowers users to meet regulatory and sustainability requirements at a pace that works best for business now and moving forward, with a variety of options including:

- high-efficiency diesel TRUs

- all-electric TRUs

- alternative fuel sources for TRUs (e.g., HVO, hydrogen, and more)

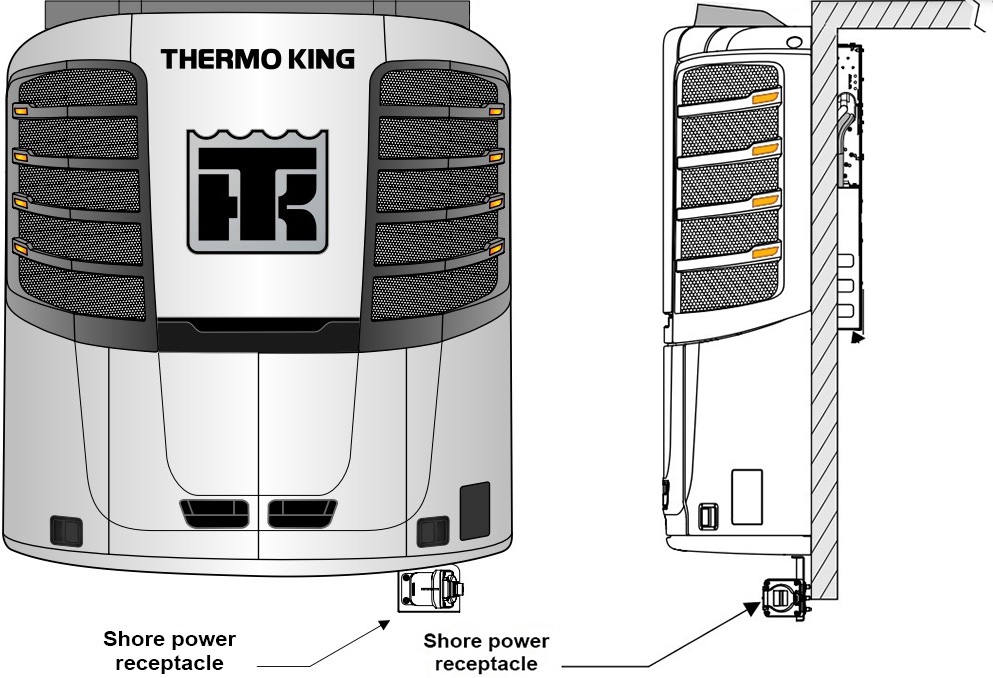

Thermo King shore power infrastructure is currently the quickest way to reduce dependence on hydrocarbons in transport refrigeration fleet operations. However, each fleet has unique needs, and there are several reliable and flexible solutions catered to specific geographies, considering natural advantages and regulatory requirements.

Figure 1: Front and side view of Precedent™ S-750i shore power receptacle.

For example, Thermo King evolve™ electrified transport refrigeration solutions help truck, trailer, bus, rail, and marine customers comply with complex regulatory requirements present in certain locales, simplifying the switch to ZE commercial fleets (Figure 2). In these cases, Thermo King manufactures and sells its components with eligibility for government rebates and incentives specifically in mind, while educating its customers regarding ESG initiatives and compliance.

Figure 2: Thermo King evolve™ electrified transport refrigeration solutions help fleet operators comply with increasingly complex regulatory requirements and reduce emissions.

These and other solutions align with the transport industry, leveraging tractor power advancements to benefit trailer TRU, and vice versa. The solutions also support scaling to make growth and adoption easier fleetwide.

Additionally, refrigerated fleet monitoring and dashboards are becoming increasingly common, and these are now nearly essential to every optimization effort because they inform users about real-time status, while providing the data and reports required to prove effectiveness. These digital solutions keep operators and administrators up to date on operational health, and they can provide diagnostics in the event of suboptimal performance, helping assure proper cooling by the most efficiently powered means possible.

Alternative power generation solutions

Today’s most viable eco-friendly solutions are partially driven by alternative power sources (non-hydrocarbon), in addition to more efficient diesel engines. Even if manufacturing centers were able to keep up with demand for all-electric fleets, the grid, as it stands today in most regions, would not be able to power a full switch. However, onboard technology and electrical infrastructure continue to advance, and the following four power generation solutions are showing increasing promise to help fleet operators meet decarbonization goals.

eAxle Technology

eAxle regenerative braking recovers and generates electricity from a trailer’s normal operation to provide cooling in trailers independent of the tractor. This is presently the most mature of TRU alternative power sources, particularly in Europe, where eAxle solutions are being actively pursued. This technology is expected to steadily roll out in North American markets as well.

Regenerative braking is the opposite of powering a motor to accelerate a vehicle. Instead, the motor is spun to slow the vehicle, simultaneously acting as a generator, which produces AC power that is then inverted to DC. This energy is stored in a battery and used to power the refrigeration unit, whether the trailer is moving or stationary.

This method is effective for short-, medium-, and long-haul applications. The technology can be seamlessly integrated into existing fleets without requiring any engine alterations, and it is compatible with almost any electric-powered TRU.

Roof-mounted solar

Solar panels provide a sustainable power management solution for truck and trailer refrigeration units, effectively increasing available power from battery systems, while reducing fuel consumption and emissions. Solar experienced a surge in popularity over the last decade in transport applications, appearing alongside TRU batteries, liftgates, and chassis batteries. Unfortunately, the strong performance in these applications has created the false perception that solar is equally valuable in multikilowatt TRU applications.

Solar panels are effective for supplementary power, but even at peak efficiency of 22% or more, their low rate of power generation potential to panel surface area cannot reliably run transport refrigeration units by themselves. Solar power may be implemented in the near-term in specific applications, but it is a costly option because of the limited power produced. Additionally, panels can be damage-prone in normal fleet operations, requiring frequent maintenance.

Solar input is also highly variable based on weather and region. This sort of uncertainty makes it difficult for fleet operators to properly equip their rigs and plan stops along a route. Making unplanned stops to charge batteries in the middle of a day is highly disruptive to logistics.

Finally, performance degradation is another concern. Dents and dings from rocks, in addition to soiling, reduce solar panel performance in as little as a year, creating an output loss of 2-25%.

Electric power takeoff (ePTO)

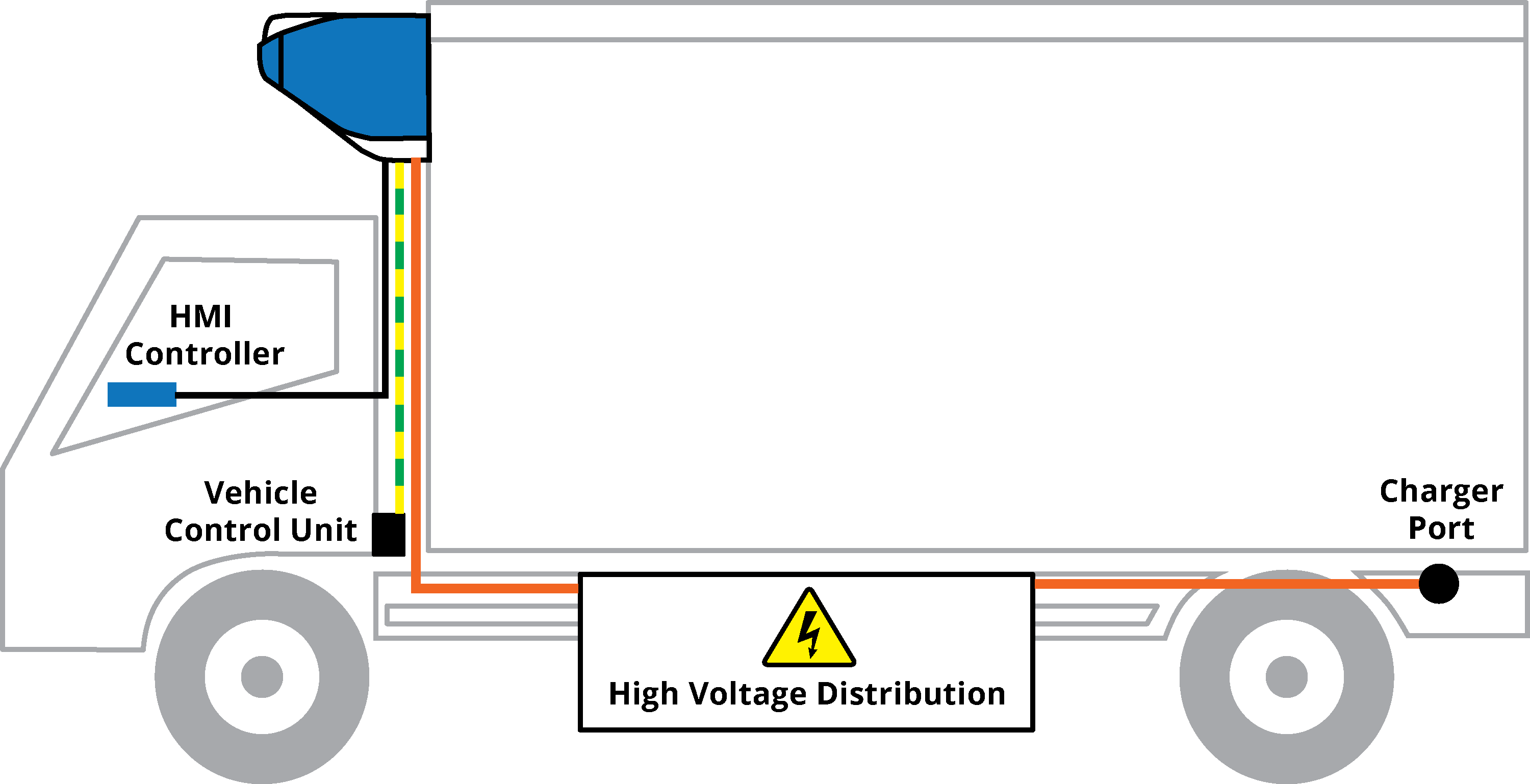

Fleets can benefit by using vehicular energy to power accessory equipment. This promising technology, known as ePTO, reduces the burden of designing TRUs for the highest-power use cases by providing power sharing from the truck engine. This method leverages vehicular electrification advances to also benefit refrigeration, improved by the economies of scale advantage inherent to EVs. ePTO requires specialized cables capable of transferring high power between the two units (Figure 3).

Figure 3: Electric power takeoff (ePTO) provides power sharing between the vehicle and TRU, allowing TRUs to leverage vehicular electrification advances to increase cooling system efficiency, reliability, and sustainability.

This method could decrease motive chassis range, but fleets could benefit from TRU cost and weight reductions, and additionally enables the TRU to only draw power in times of need.

Fuel cell

Hydrogen fuel cells provide a promise of clean, ZE power generation capabilities for truck and trailer TRUs. The power/weight ratio is superior and fueling/recharge time is shorter compared to battery-powered options, but the required ancillary components are costly and require abundant space. Additionally, there is currently limited fueling infrastructure.

Although this technology is not yet ready for prime time, its availability may be accelerated by the development of hydrogen-powered consumer vehicles.

Creating options for efficiency

Thermo King is leading the industry in designing and implementing innovative electric technology, which began decades ago with electric technologies for marine, bus, and truck product lines. In recent years, the electrified portfolio has expanded significantly with low- and zero-emission solutions in every segment of the end-to-end cold chain, and with power management offerings and HVAC systems for public transit.

By electrifying solutions and supporting rollouts, Thermo King is revolutionizing transportation, creating a more efficient cold chain and a sustainable planet for generations to come. These electric transport refrigeration units are scalable, resilient, and modular, simplifying design, deployment, and support.

Thermo King works with its partners to prototype and test full systems, providing users with successful transition strategies upon implementation. It also actively engages with regulatory agencies to share industry perspectives and communicate the voice of its customers. Thermo King is committed to easing the transition to electrified fleets by collaborating with its customers to understand their unique needs, and to provide solutions that meet complex regulatory requirements and organizational sustainability goals. The company also helps educate its partners about governmental incentive programs and rebates so they can fit electric transformation expenditures into their budgets.

This all amounts to reduced carbon emissions, helping organizations achieve their sustainability goals.

For example the Precedent® S-750i, a diesel electric unit designed for transport fleets, retailers, and pharmaceutical companies seeking solutions that are more efficient in their use of electric power. This unit provides operational cost savings, greater uptime, and lower emissions. In 2022, Thermo King transitioned this and other truck and trailer products to R-452A refrigerant, with reduced global warming potential compared to its predecessor.

Thermo King additionally approved the use of hydrotreated vegetable oil (HVO), a fossil-free fuel, as a more sustainable fuel alternative to power its traditional diesel product lines in 2023. HVO is typically viewed as superior to regular biodiesel and does not release any new carbon dioxide into the atmosphere. It can be used in place of diesel with no modifications to a Thermo King unit’s engine or changes in its preventative maintenance schedule.

These are just some of the ways Thermo King is working to reduce emissions in the global cold chain ahead of regulation, while ensuring reliable operations so products do not spoil.

Time to act

Since 2021, Thermo King has invested more than $100 million developing fully-electric products in every segment of the cold chain, as well as alternative fuel technologies. Additionally, Thermo King’s parent company, Trane Technologies, has committed to reducing one gigaton—one billion metric tons—of carbon emissions CO2e from its customers’ footprints by 2030. This Gigaton Challenge is the first B2B company climate commitment of its kind.

Thermo King aids its customers with the infrastructure for long-term operations and on-the-road support. This includes its vast dealer network throughout the United States and Canada, comprised of over 185 locations, more than 800 service bays, over 500 mobile trucks, aftermarket parts and accessories, and more than 900 factory-certified technicians (Figure 4). Additionally, meaningful data and analytics through the TracKing® telematics platform can extend the life and enhance performance of refrigeration assets (see Sidebar).

Figure 4: Thermo King has a vast dealer network throughout the United States and Canada that includes over 900 factory-certified technicians.

The decarbonization journey for each fleet operator is unique, and regardless of the motivation for changes—be it regulatory compliance, rebate incentives, ESG goals, or some combination of the three—there is an individualized path every company can follow. By transitioning to more sustainable fleets, organizations can reduce lifetime total cost of ownership through efficient operations, conform to regulatory standards, and reduce emissions, ultimately stewarding the earth for future generations.

It will take everyone to preserve the planet, and adopting electrical and other alternative energy sources for TRUs is one way fleet operators can do their part. As with all significant change, there will be growing pains. However, in the coming decades, decarbonization will help the transport industry meet mounting social pressure and regulatory requirements, while keeping fleet operational costs in check.

Digital Solutions

In today’s complex world of logistics management, monitoring cargo and assets is a requirement. Innovative digital solutions provide not only raw data, but a way to intuitively visualize up-to-date material status and equipment performance. The fleet performance dashboards built into TracKing® telematics, for example, empower telematics subscribers to analyze and monitor refrigeration and power performance for each individual truck and trailer, in addition to providing fleetwide metrics (Figure 5).

Figure 5: TracKing® telematics subscribers can easily analyze and monitor their refrigerated fleet performance with dashboards highlighting overall fleet and individual vehicle group operation, alarm summaries, and zone metrics.

Visualization and reporting solutions help prove the effectiveness of decarbonization efforts and identify opportunities to further increase efficiency. To track fleet assets, cellular connectivity is required. TracKing telematics is a 4G LTE temperature and asset management system that provides end-to-end visibility across a variety of devices, including PCs, tablets, and smartphones. The technology provides real-time and historical temperature data alongside fleet information to help increase fleet efficiency and reduce the likelihood of cargo loss. Additionally, the platform helps inform maintenance teams of the ideal time to bring in vehicles for servicing, increasing uptime and the life expectancy of equipment.

To help improve the level of real-time intelligence available to fleet managers regarding the condition of their refrigeration equipment, Thermo King developed the Thermo King Connect mobile app, which keeps operators connected to their assets (Figure 6). This app is available in the Android and iOS app stores, and it syncs to the cloud-hosted central software hub, ConnectedSuite™.

Figure 6: The Thermo King Connect mobile app keeps fleet operators informed of their loads and refrigeration efficiency at all times.

Data can be put to work in many different ways, such as improving route efficiency, implementing more effective driver training, and detecting instances of fuel loss. Through these and other efforts, ConnectedSuite helps operators plan better.

Knowing exactly when a problem arises and gaining the visibility needed to initiate effective responses empowers fleet managers to address issues quickly so they can keep trucks and trailers on the road. These and other benefits are available around the clock to help improve operations.